For every great shirt there’s a process to get there. Here’s a quick list just to give you an idea of what’s involved.

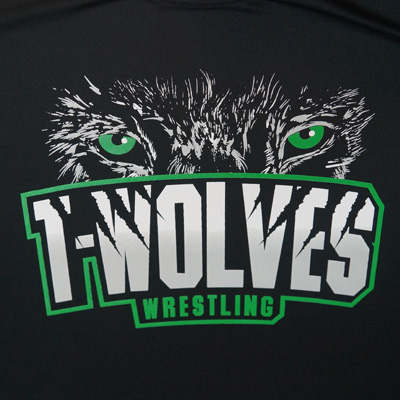

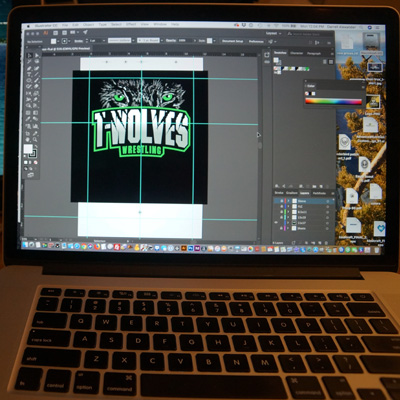

Pick out your garments, and then we’ll start designing the graphics. We’ll refine the artwork together until everything is approved and exactly how you want it.

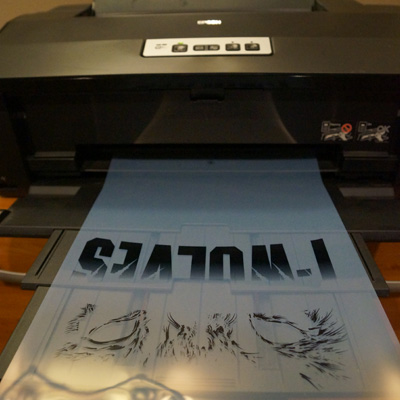

Print the film outputs, then coat a clean screen with emulsion. Once it’s coated, place the screen in the drying cabinet to fully dry before moving on to the next step.

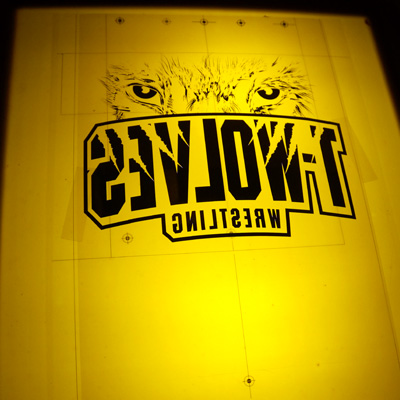

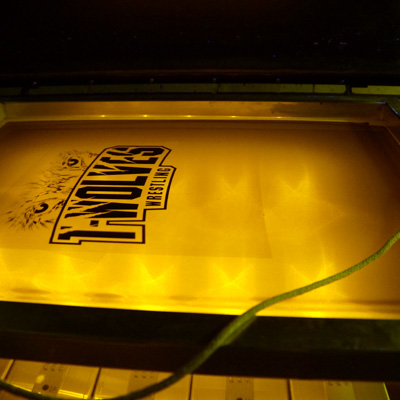

Register the film on the screen, then expose it in the exposure unit to burn the image into the emulsion.

Wash out the screen in the washout booth, then place it back in the drying cabinet to fully dry before printing.

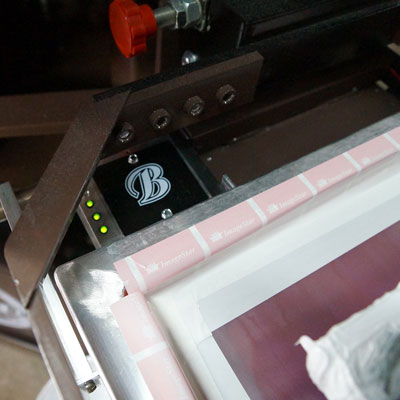

Tape off the screen and register it on the press so it’s aligned and ready for printing.

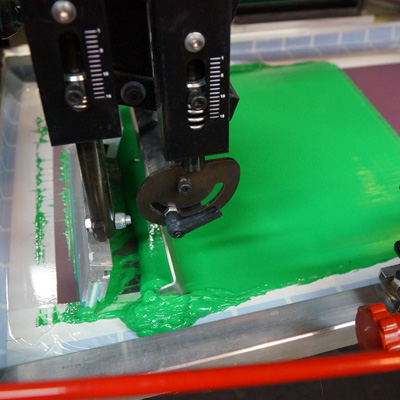

Put the ink on the screens and run a test print to check your registration. Make any micro‑registration adjustments as needed to ensure everything lines up perfectly.

Double‑count the shirts to confirm the quantities. Then program the press and start printing the shirts.

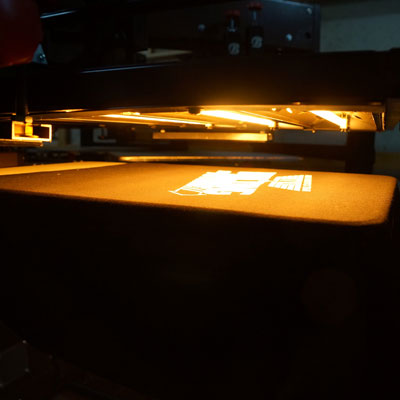

Put the shirts through the dryer to fully cure the ink. Once they’re cured, count the shirts again for accuracy and box them up for delivery or pickup.

Remove the tape from the screen and clean the ink off thoroughly. Then place the screen in the dip tank to remove the emulsion so it’s ready for reclaiming.

Wash the screen in the washout booth using a power washer to remove any remaining emulsion. Then scrub the screen with dehazer to clean and restore the mesh.

Give the screen one final rinse, then place it in the drying cabinet so it’s ready to start the process all over again.